321 stainless steel plate corrosion will produce pits, because poor rolling can also cause surface pits, hot rolled steel surface pits often appear in the upper and lower surface of the steel plate, and the upper surface is more serious, the shape is polygonal, round or oval Shape, etc., have no regular distribution, and no significant rolling direction extension, is a push-in surface defect. Guard slag elements such as Ca and Al were not detected at the pits. The defects were not related to the protective slag. The pits were caused by crushing the oxide scale and pushing it into the surface of the steel plate. For such pit defects consisting solely of oxide scale, the improvement measures are:

1. Optimize the rolling process, control the thickness of oxide scale and the formation of pits. The formation of pits is related to the final rolling temperature. The final rolling temperature is easily formed between 810-850°C. The pit defects should be formed easily. The final rolling of SUS304 stainless steel plate should be increased as much as possible. The temperature keeps the scale hardness on the surface of the steel sheet within a small range, so that the scale is not easily pressed into the surface of the intermediate during rolling. In order to ensure the performance of the steel sheet and reduce the thickness of the surface oxide scale formed on the cooling bed, laminar cooling can be used.

2. Reasonably formulate descaling process and improve descaling efficiency When the intermediate billet is rolled into the second stage, the descaling effect of the first pass shall be guaranteed on the premise that its surface temperature is allowed. During rolling to the last few passes, in order to avoid the formation of pit defects on the surface of the intermediate billet by the newly formed triple oxide press, full descaling should be performed in the last few passes, and the pressure of the descaling system should be maintained at 16-20 MPa. . In addition, fine descaling nozzles should be arranged according to the width of the steel plate, and fine descaling time should be adjusted according to the length of the steel plate and the roller conveyor speed so as to ensure that the high pressure water jet can cover the entire steel plate.

The application practice shows that under the premise of guaranteeing the performance of the steel plate, it is an effective method to eliminate such black spot pit defects after descaling and after a few times of finishing rolling.

1. Optimize the rolling process, control the thickness of oxide scale and the formation of pits. The formation of pits is related to the final rolling temperature. The final rolling temperature is easily formed between 810-850°C. The pit defects should be formed easily. The final rolling of SUS304 stainless steel plate should be increased as much as possible. The temperature keeps the scale hardness on the surface of the steel sheet within a small range, so that the scale is not easily pressed into the surface of the intermediate during rolling. In order to ensure the performance of the steel sheet and reduce the thickness of the surface oxide scale formed on the cooling bed, laminar cooling can be used.

2. Reasonably formulate descaling process and improve descaling efficiency When the intermediate billet is rolled into the second stage, the descaling effect of the first pass shall be guaranteed on the premise that its surface temperature is allowed. During rolling to the last few passes, in order to avoid the formation of pit defects on the surface of the intermediate billet by the newly formed triple oxide press, full descaling should be performed in the last few passes, and the pressure of the descaling system should be maintained at 16-20 MPa. . In addition, fine descaling nozzles should be arranged according to the width of the steel plate, and fine descaling time should be adjusted according to the length of the steel plate and the roller conveyor speed so as to ensure that the high pressure water jet can cover the entire steel plate.

The application practice shows that under the premise of guaranteeing the performance of the steel plate, it is an effective method to eliminate such black spot pit defects after descaling and after a few times of finishing rolling.

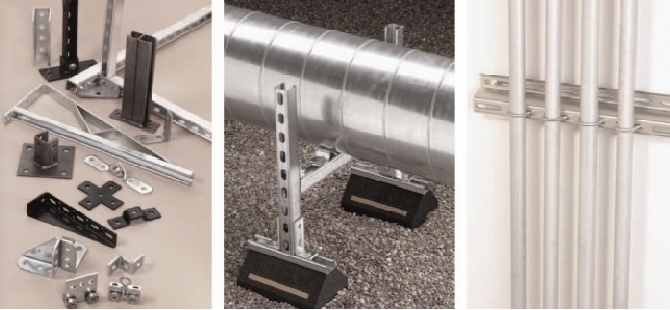

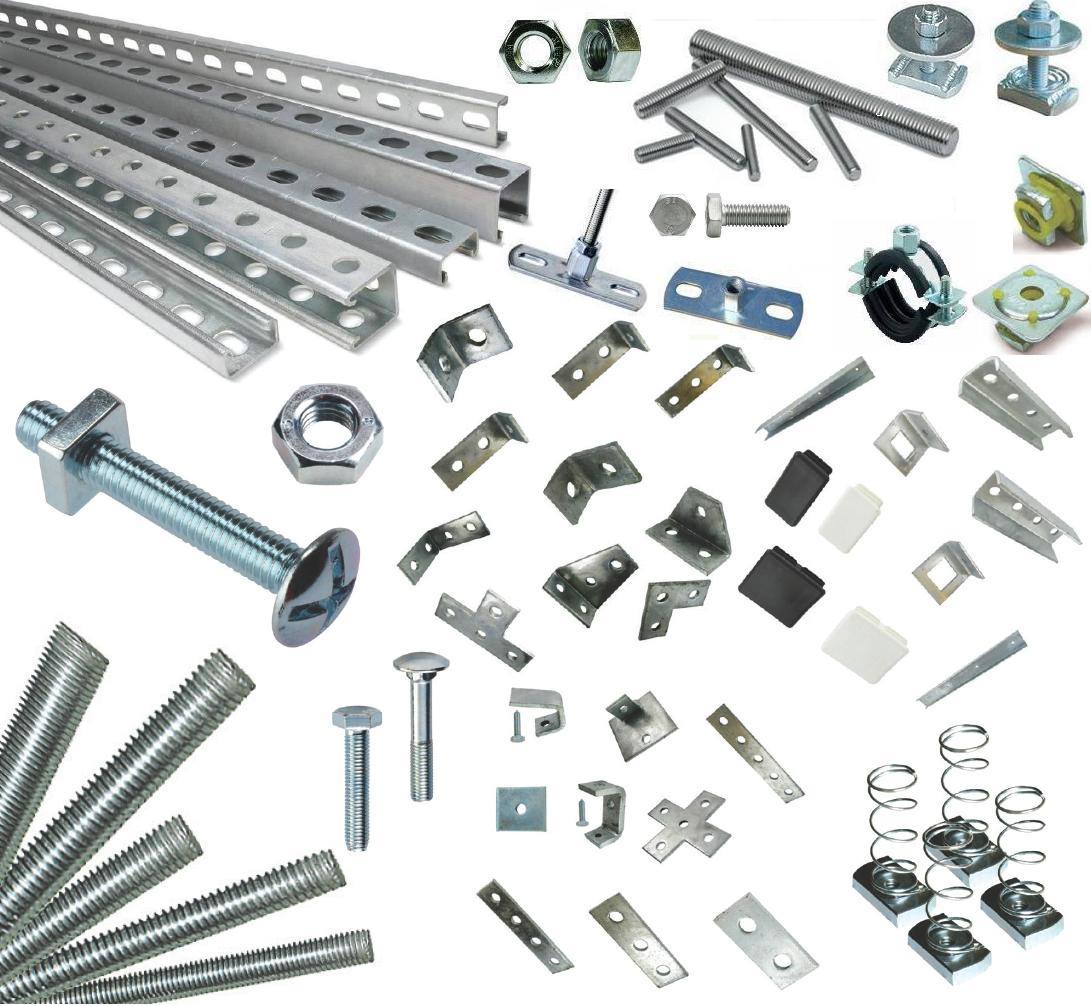

Strut System & Accessories

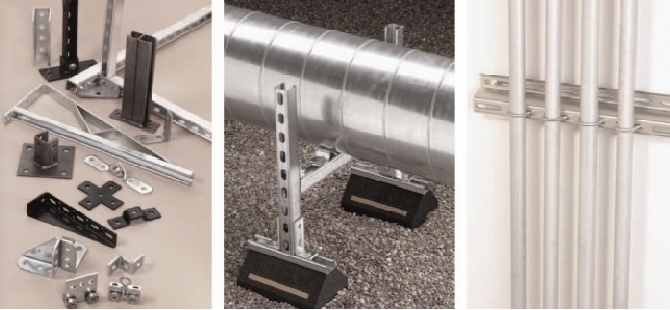

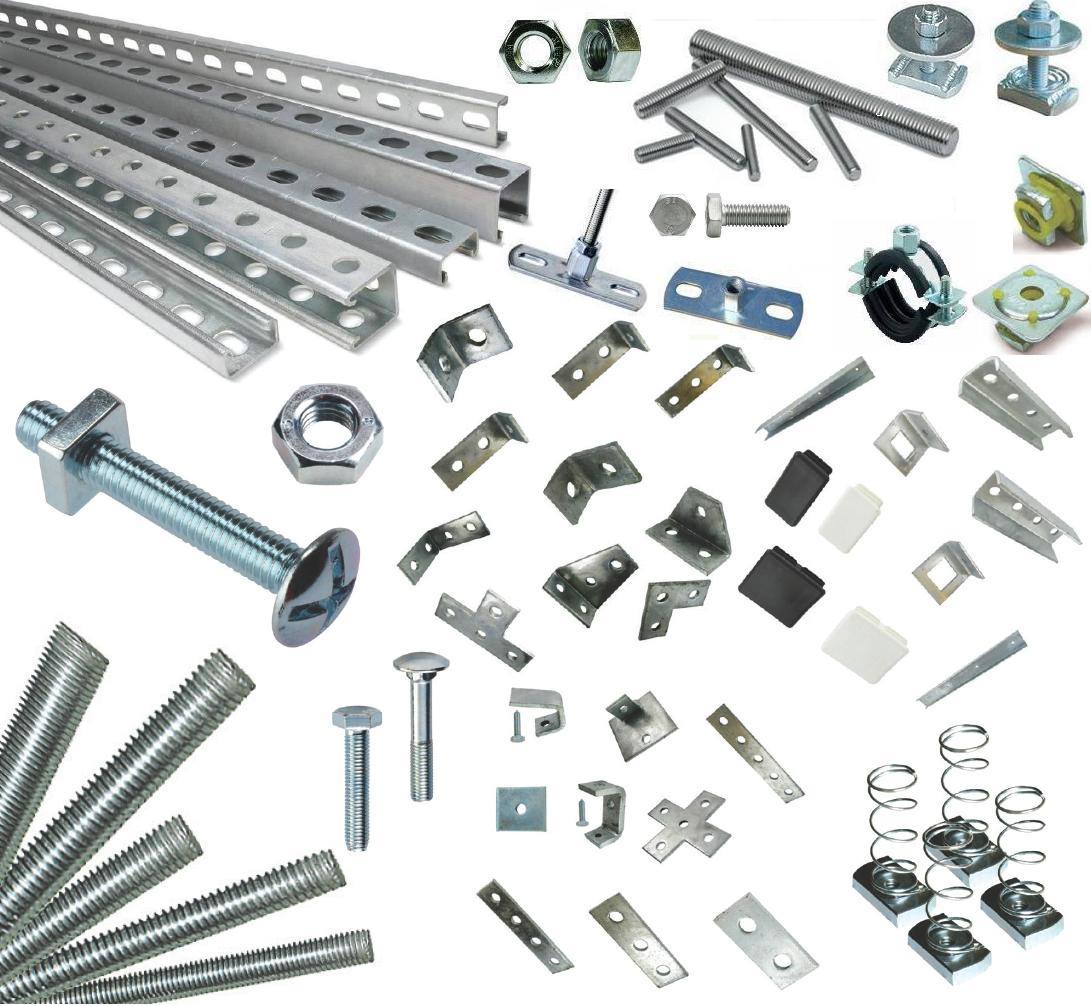

Yokelink is a professional manufacturer and fabricator of steel and aluminum series products which are used in support of equipment for industrial, commercial, utility, and OEM installations. We are proud of the exacting standards of research, design, engineering, and manufacturing that go into each and every product that comprise our strut product line. Our customers have access to one of the most complete support strut systems offered in the industry, including metal framing, cable tray, pipe hangers, slotted angle, and fasteners.All of our strut system products are manufactured to meet or exceed Metal Framing Manufacturers Association (MFMA) and other industry standards set for their design and manufacture.

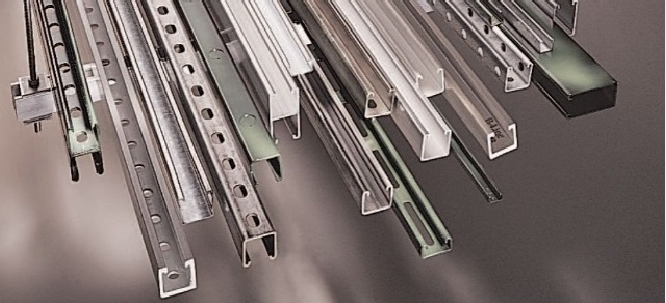

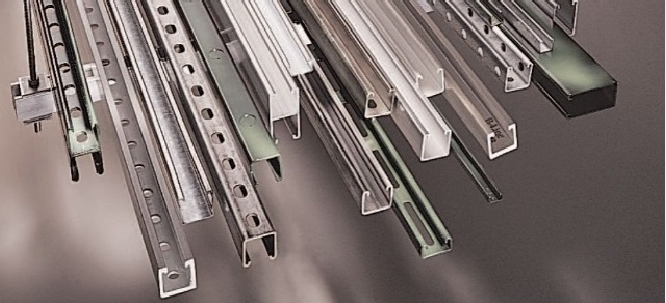

Our strut system including series of strut channels,metal framing system,angle fittings,cable tray,pipe hangers and fasteners. Hardware, Fittings, Mechanical & Electrical Accessories,Special Materials (Aluminum, Stainless Steel, Fiberglass),Mini Channel, Concrete Inserts, Slotted Angle...etc

Features

• Easy integration and configuration

• Comprehensive library of 2D drawings and 3D models for CAD, BIM, PDMS, SP3D,

and graphics output

• Up-to-date software versions and product data information

• Submittals and specification sheets in PDF format

• Proprietary file format outputs are native to the chosen software

Yokelink Metal Framing System Catalog. A comprehensive guide to the world's most verstile metal framing system.From the handy table of contents to the expanded and updated te chnical data,every detail was designed for one purpose:To make your job easier.The following pages contain product drawings as well as desciptive material and supporting technical infomation that will help you make the right sepecifying or buying decision,quickly and effeciently.

Yokelink-Strut System Supplier, Strut Channel Supplier,Pipe conduit clamps supplier in china.

Strut Systems,Metal Framing System,Pipe/Conduit Installation,Strut Channel

Ningbo Yokelink Machinery Co.,Limited , https://www.yokelink.com